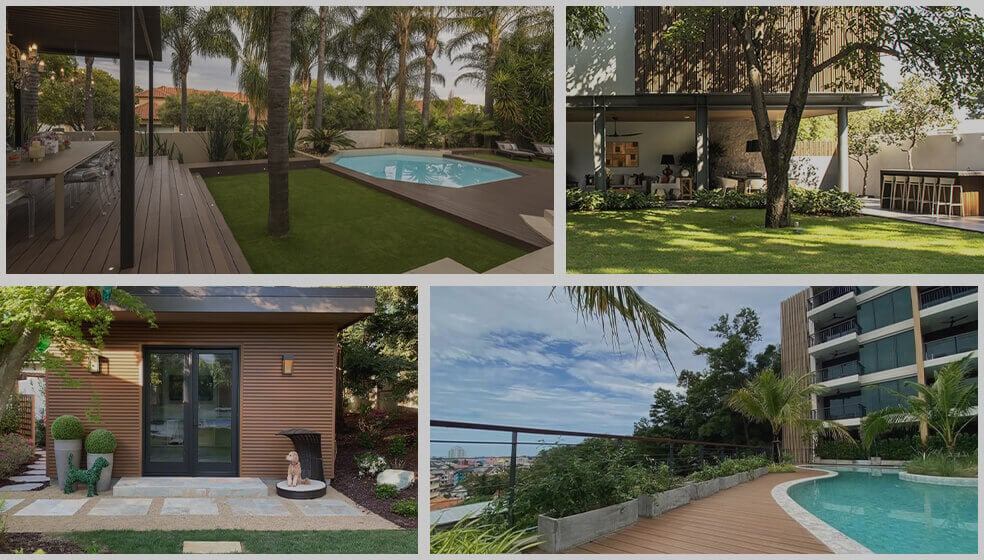

Is Composite Decking Good Around Pools?

Building a backyard pool is a great way to maximize your fun in the sun as well as boost the value of your property. As excited as you may be about your new addition, there are a lot of decisions you’ll need to make that contribute to how much you’ll…

Read MoreBest Outdoor Shower Floor Materials

Having an outdoor shower as part of your pool is convenient for rinsing off after a swim. If you’re thinking of adding one to your backyard, it’s important that you choose the right materials, especially for the flooring. You want it to be comfortable, attractive and durable. If not, you…

Read MoreHOW TO INSTALL DECK TILES

Easy installation. Fast transformations. Cost effectiveness. Endless customization of colors and patterns. If you’re a renter, when you’re ready to move on, you can break it down and take it with you. No wonder composite deck tiles are an option high on many lists when people are looking to refresh…

Read MoreHow To Install Deck Railing Posts

Building a deck creates a prime gathering spot for friends and family to enjoy the outdoors. In addition to using the right materials and techniques, it’s also critical to build your deck to be as safe as it can be. One of the most important steps for this is to…

Read MoreComposite Deck Railing vs. Aluminum Railing

When your deck project comes down to some final design choices such as aluminum vs. composite deck railings, know that you’ve already made one smart decision by not considering wood as a material. Even treated lumber decking needs far more maintenance than other outdoor materials. Painting or staining spindles or…

Read MoreBest Decking Material For Dogs

You want to spend time outside. Your dog just wants to spend time with you — and if it’s outside, so much the better. That means you’re going to need a deck that can stand up to the weather, stand up to your pets and become their haven as much…

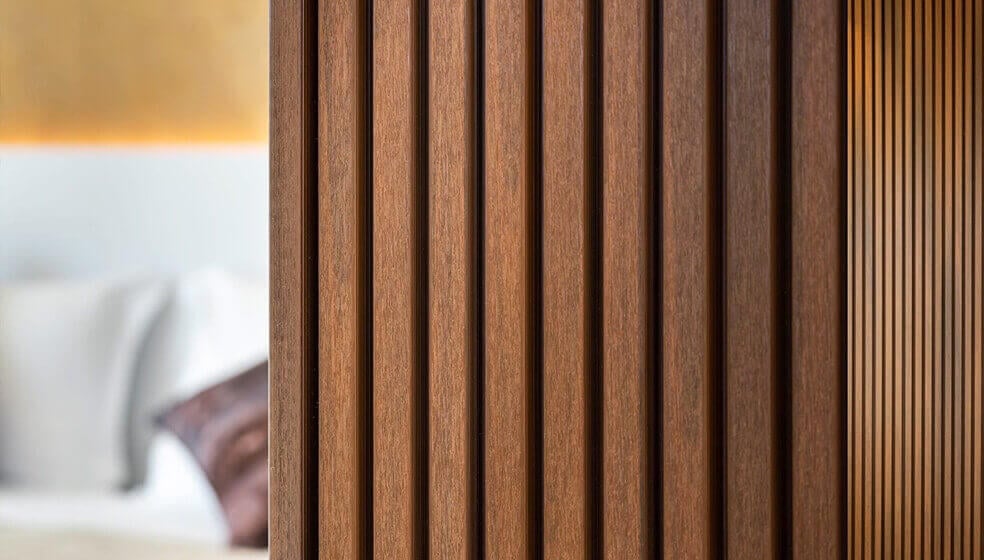

Read MoreIs Composite Decking Truly Maintenance-Free?

When you’re in the market for a new deck, you’ll likely notice a lot of the same phrases over and over, especially when you’re looking into composite decking. Typical selling points for composite decking include: Easy installation Environmentally friendly Maintenance-free Easy installation? Check — composite decking is ready for use…

Read MoreThe Most Popular Deck Colors

It used to be that choosing a color for your deck was a biennial affair, a parade of going from transparent stains to semi-transparents and finally paint as you attempted to extend the life of your treated lumber outdoor space. With the advent of low-maintenance composite decking, choosing the best…

Read MoreDoes Composite Decking Get Hot In The Sun?

If you’re shopping for decking options, one of your biggest concerns will probably be comfort. That means you’ll likely be asking the question, “Does composite decking get hot in the sun?” The short answer is yes — like everything exposed to sunlight, it can get hot. However, you shouldn’t let that dissuade…

Read MoreHow To Remove Rust Stains From Composite Decking

One of the greatest things about composite decking is that it’s designed to be easy to maintain. Unlike with wood, you shouldn’t have to spend your summers applying sealants or replacing irreparably stained boards. That’s not to say that composite decking won’t get dirty, however. It will accumulate dirt on…

Read More