ULTRASHIELD® VS. CONVENTIONAL DECKING

STAINS

| Step 1: Stain with black ink | |

|

|

|

| Step 2: Wipe out half of the ink | |

|

|

| Step 3: Wash off by water | |

|

|

| Last Step: Dry and see the result | |

|

|

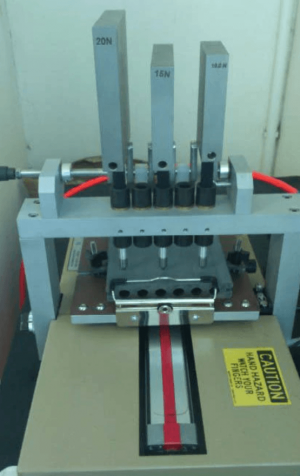

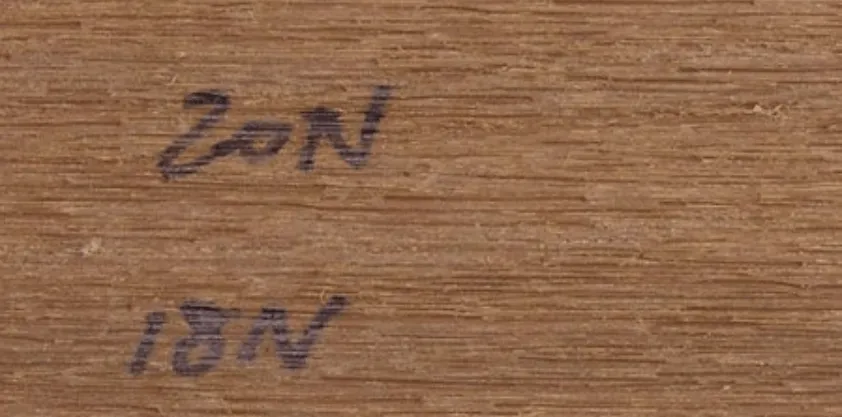

SCRATCHES

- Use 1mm needle

- Test scratch damage under 8N-20N pressure

- Test standard: FLTM BO 162-01

|

|

|

|

|

|

|

|

|

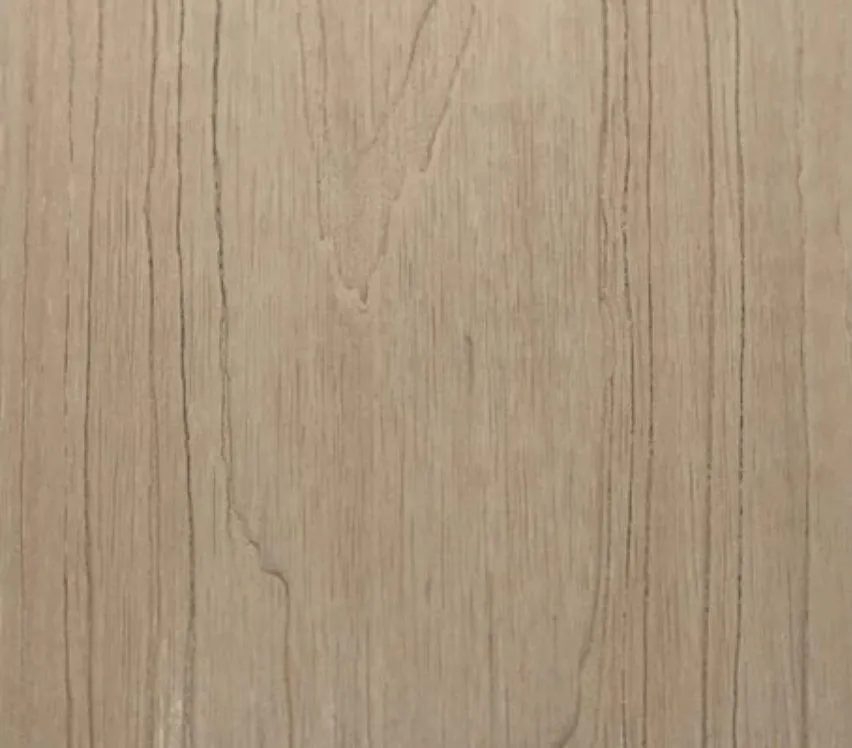

ABRASIONS

- Testing: 750g Weight, 60 turn/min, 1000 turns

- Test Standard: ASTM D4060

| Original | |

|

|

|

| Scratch mark and the wore off powder weight after test | |

|

|

|

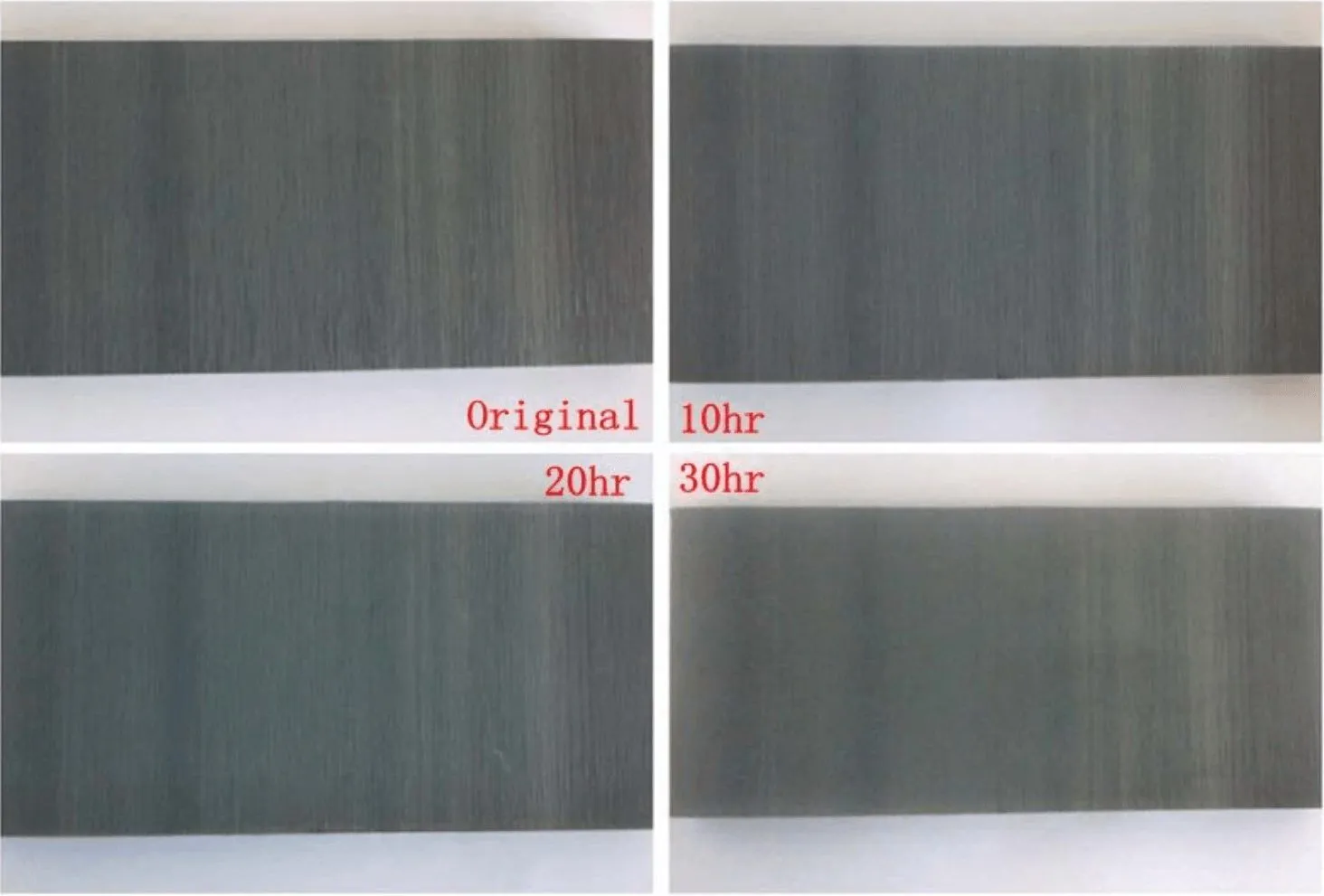

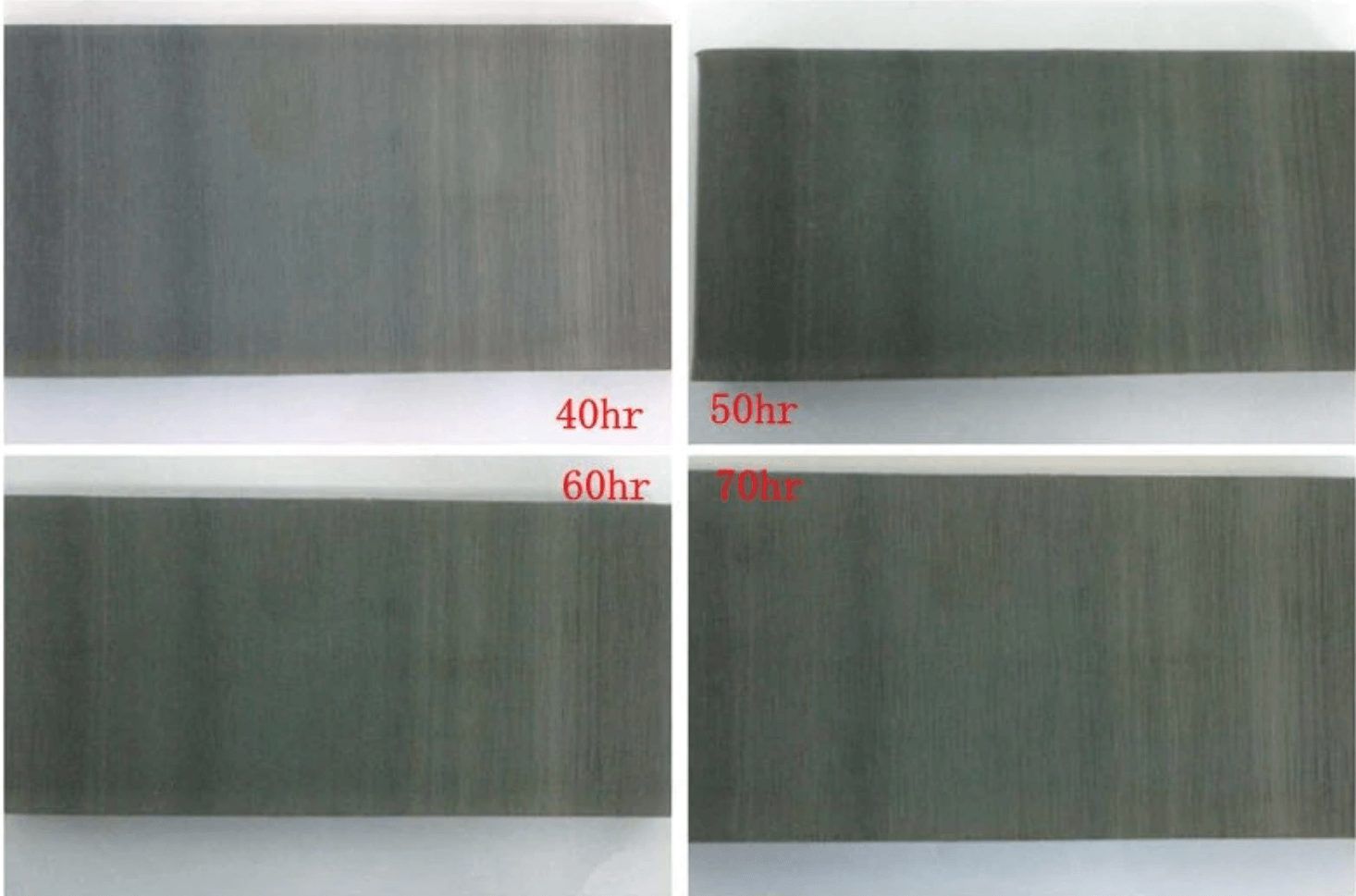

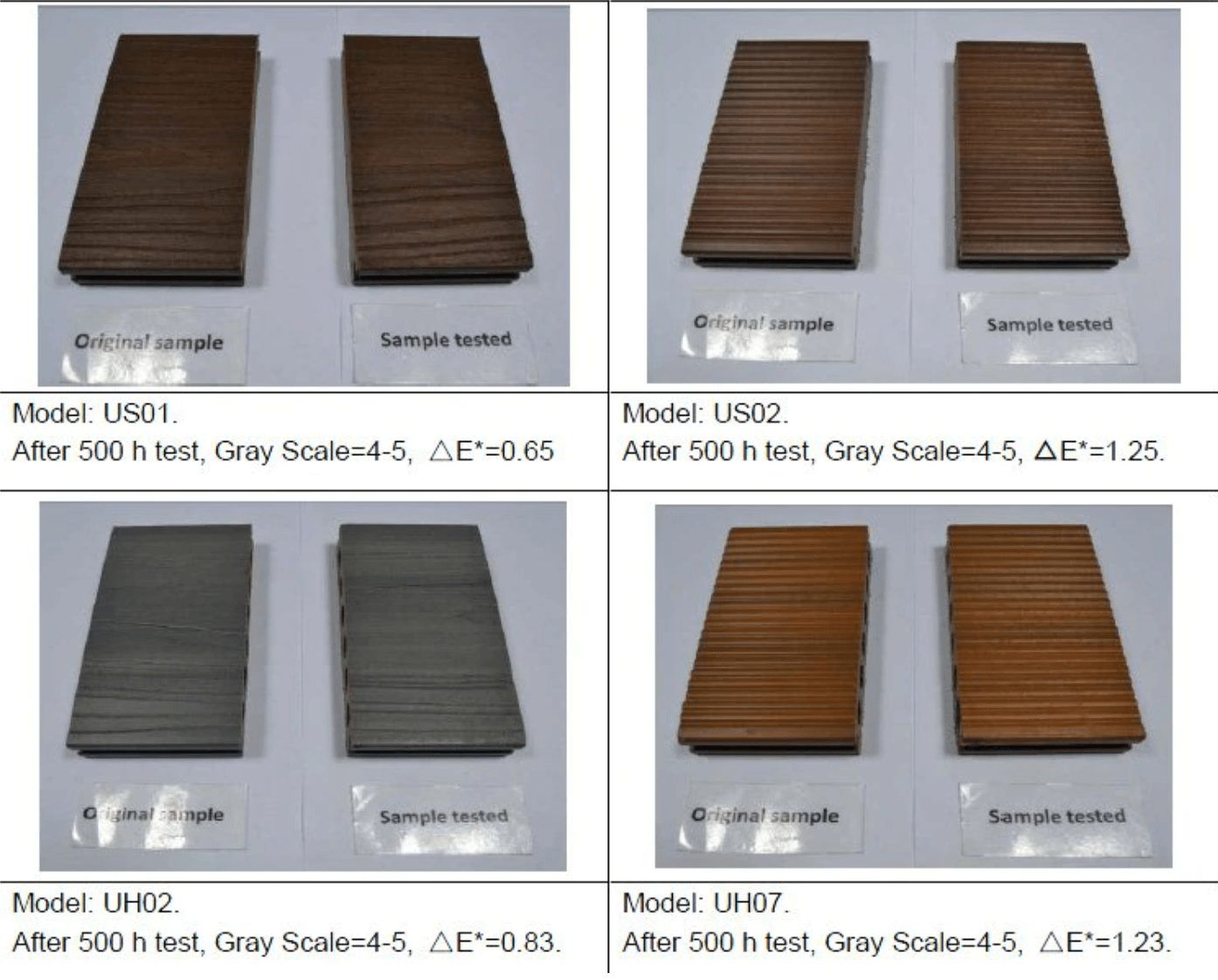

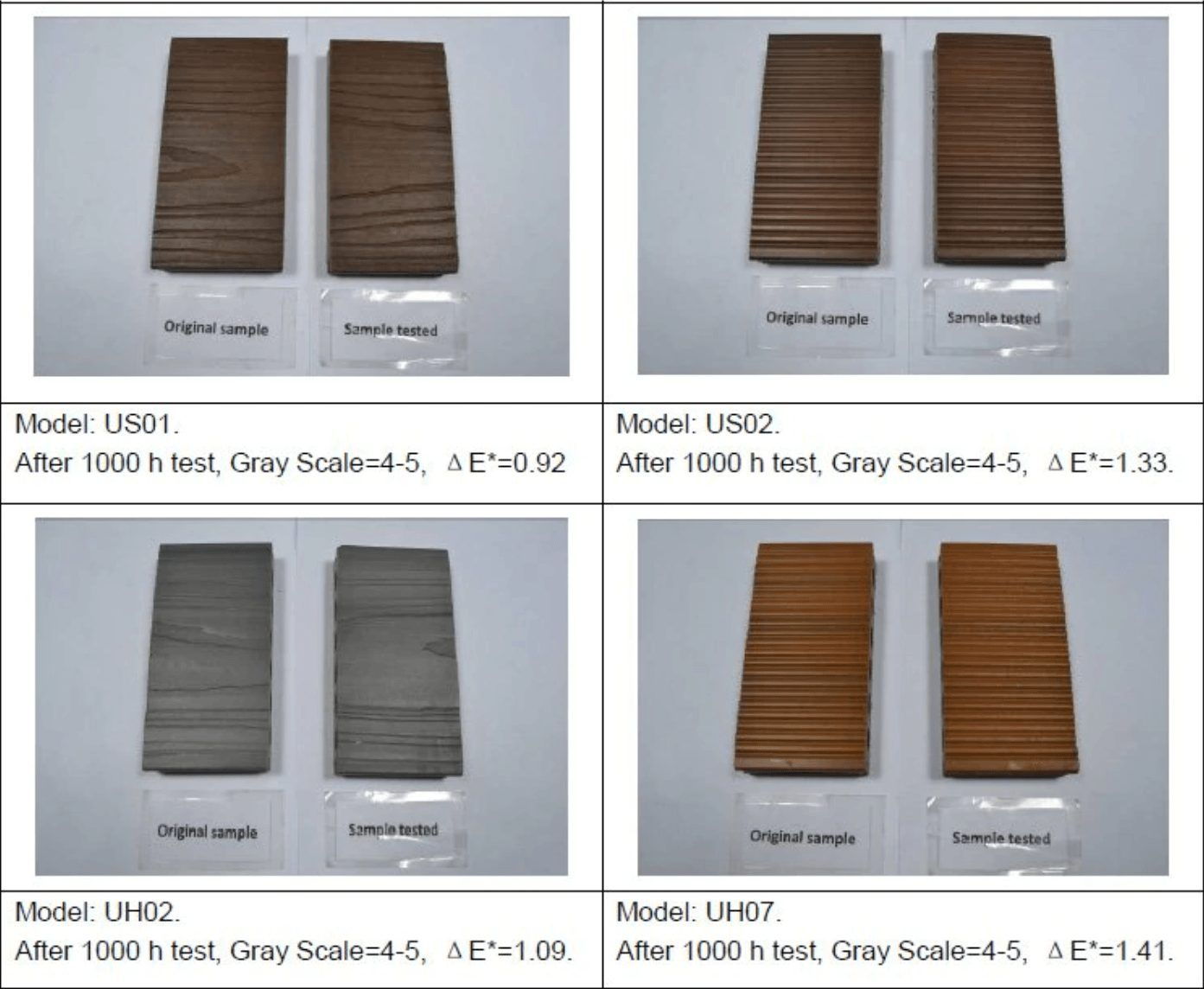

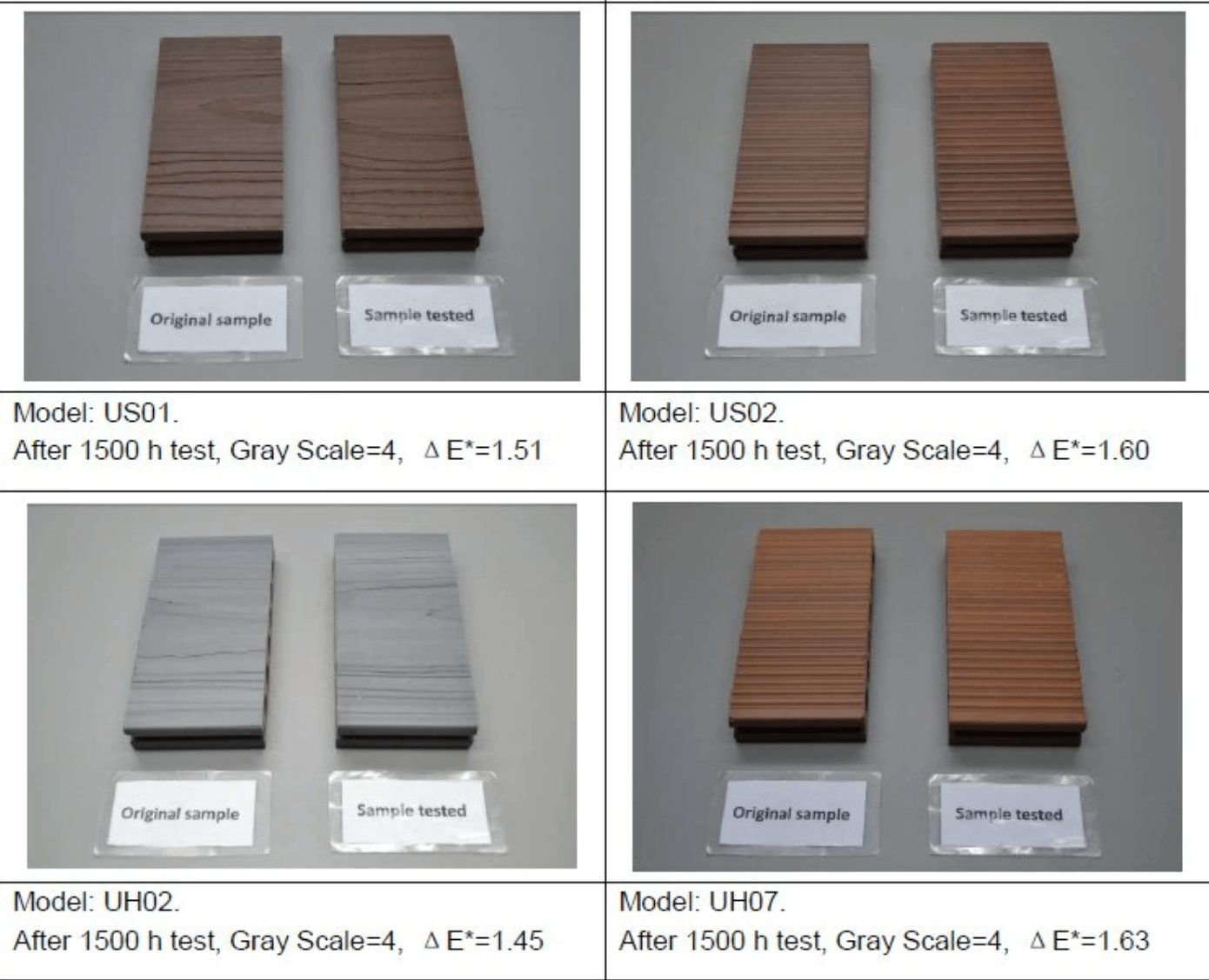

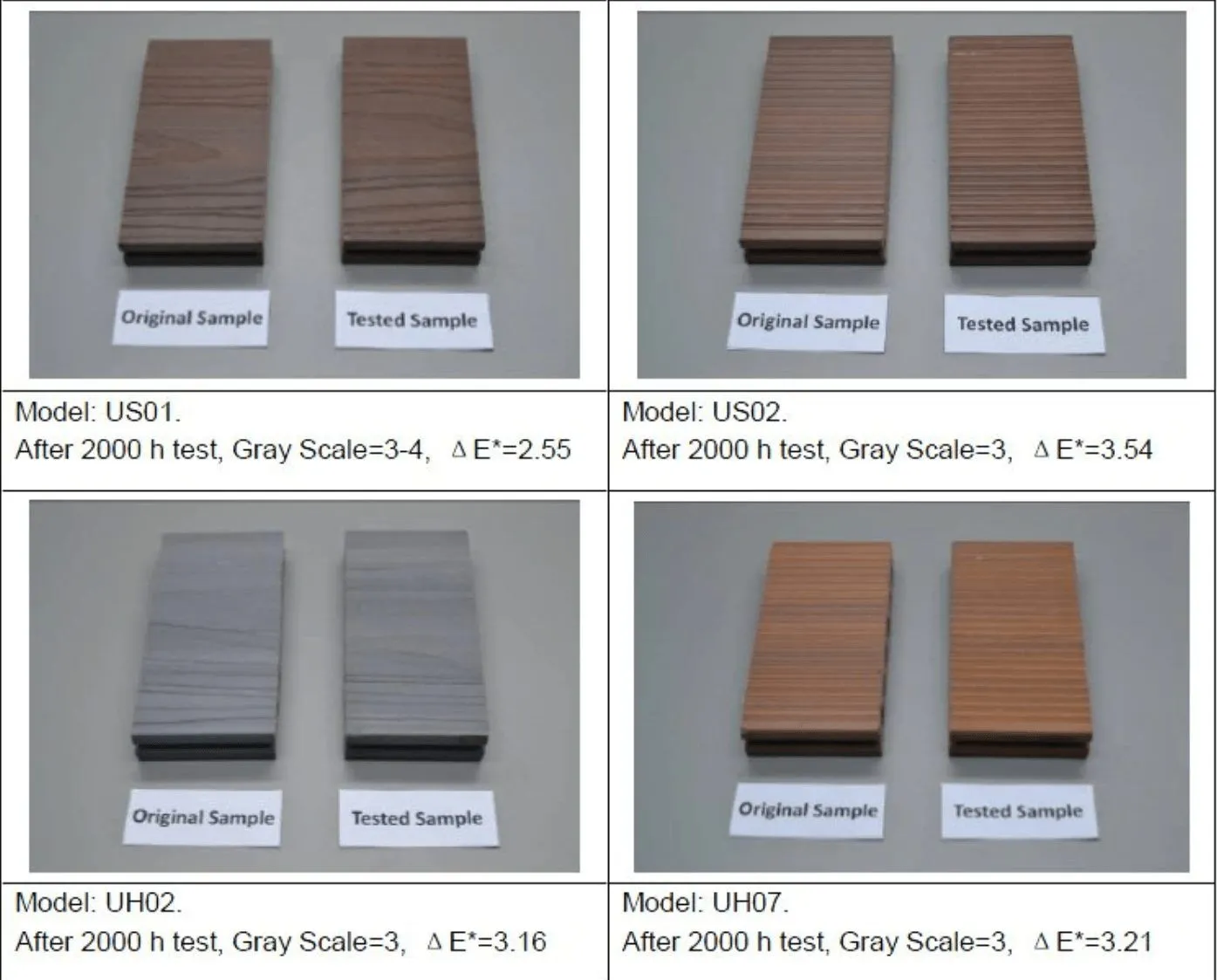

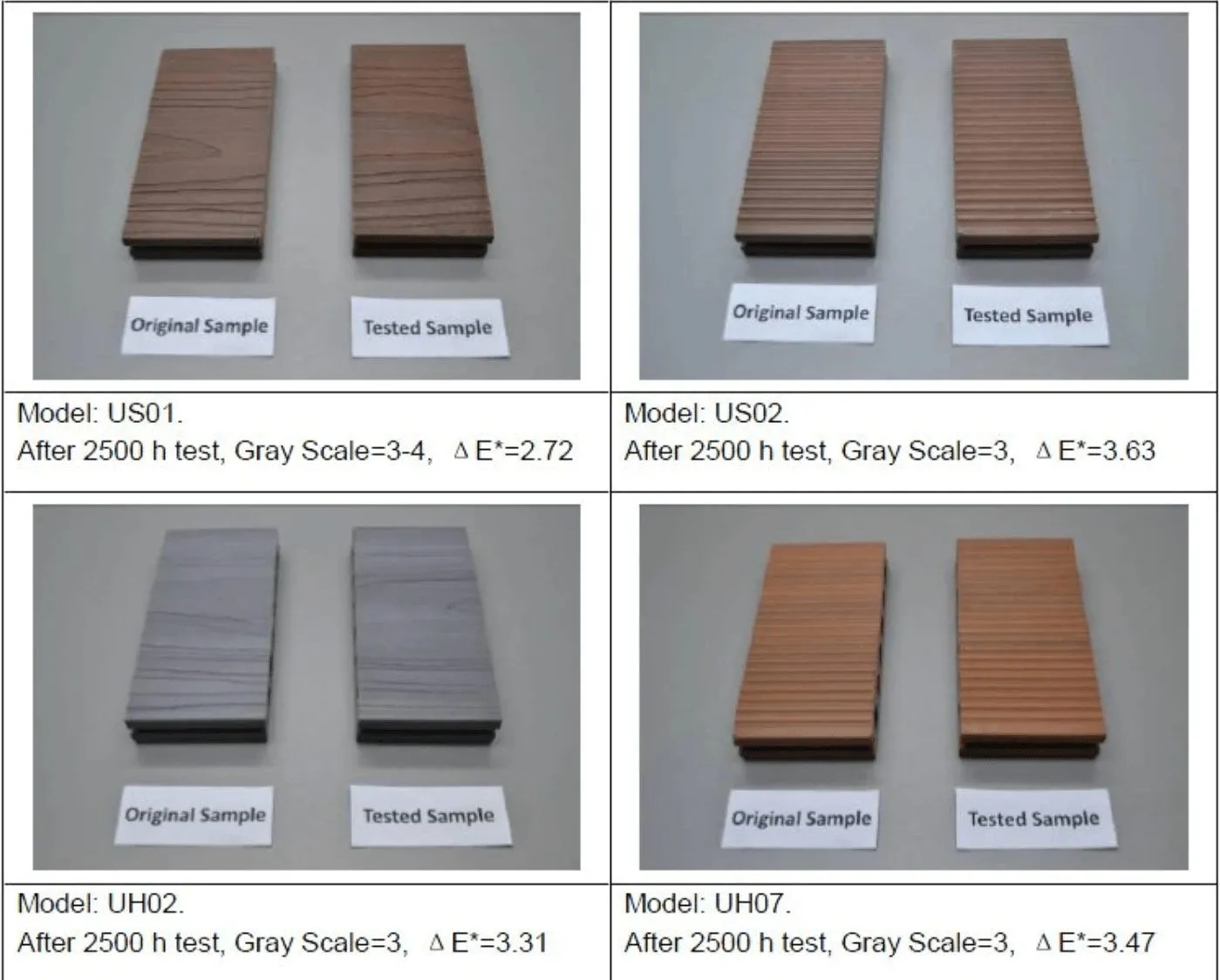

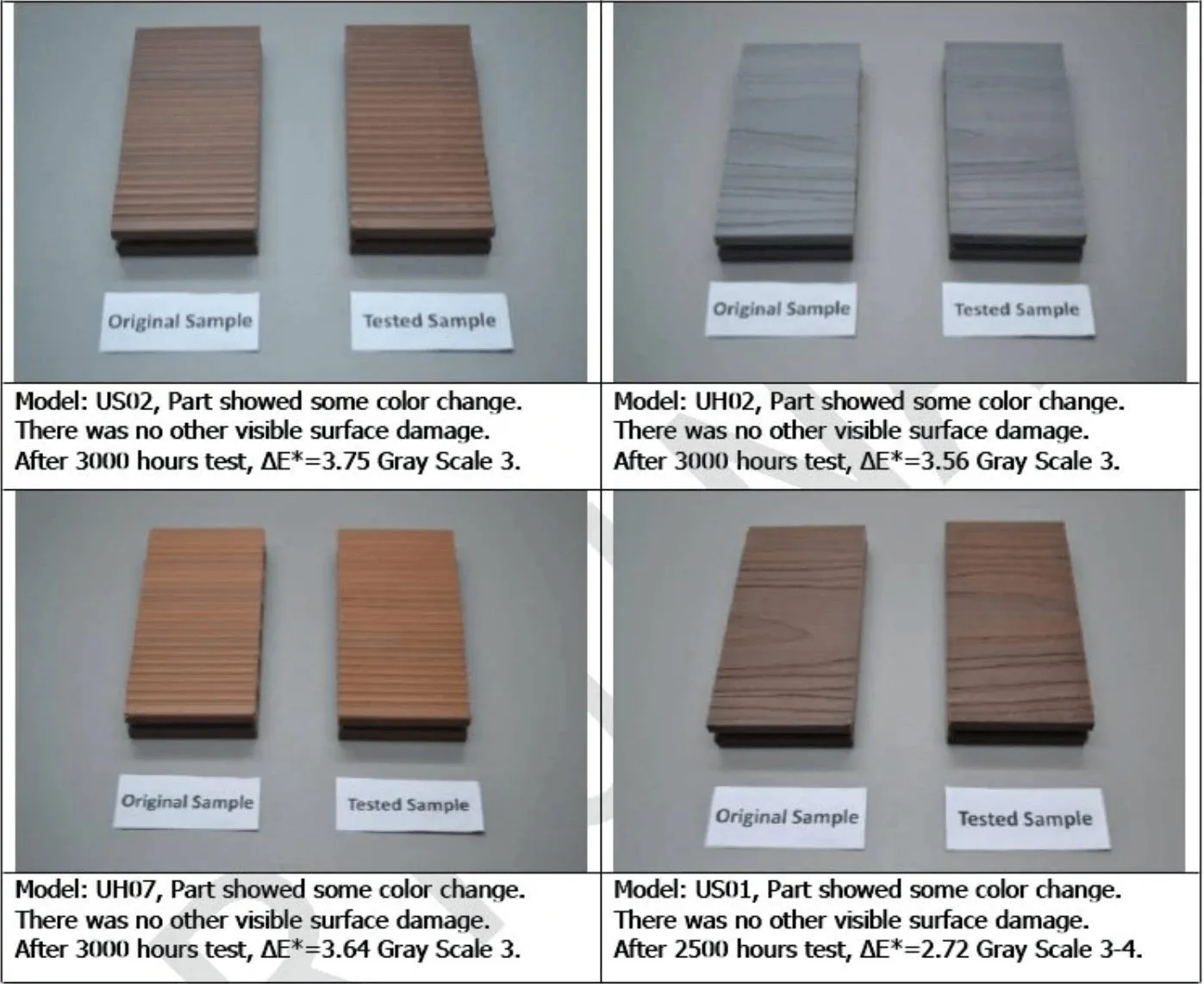

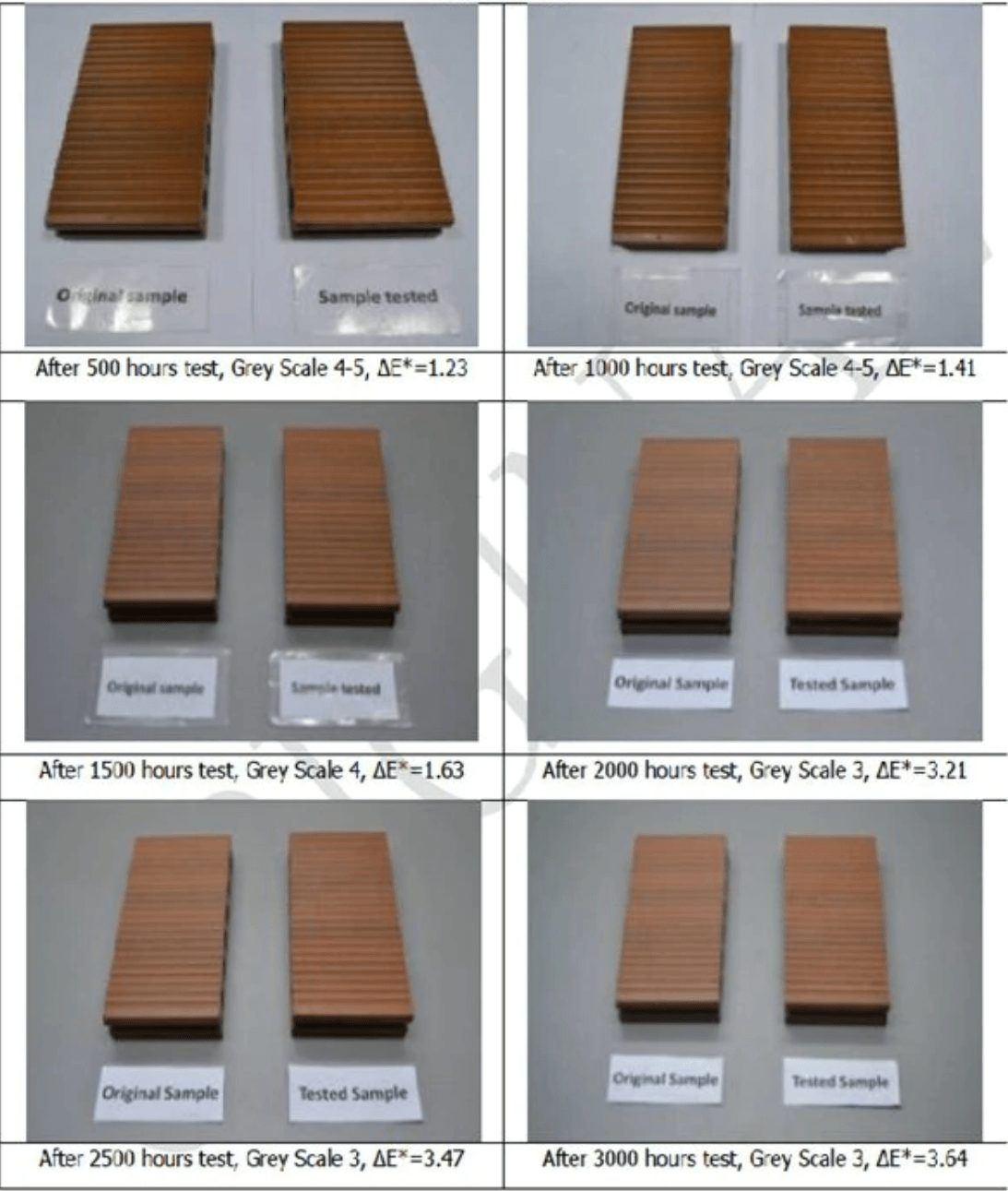

UV

QUV chamber test up to 3000 hours

Observation & record in every 500 hours

|

|

|

|

|

|

|

|

|

|

|

|

|

|

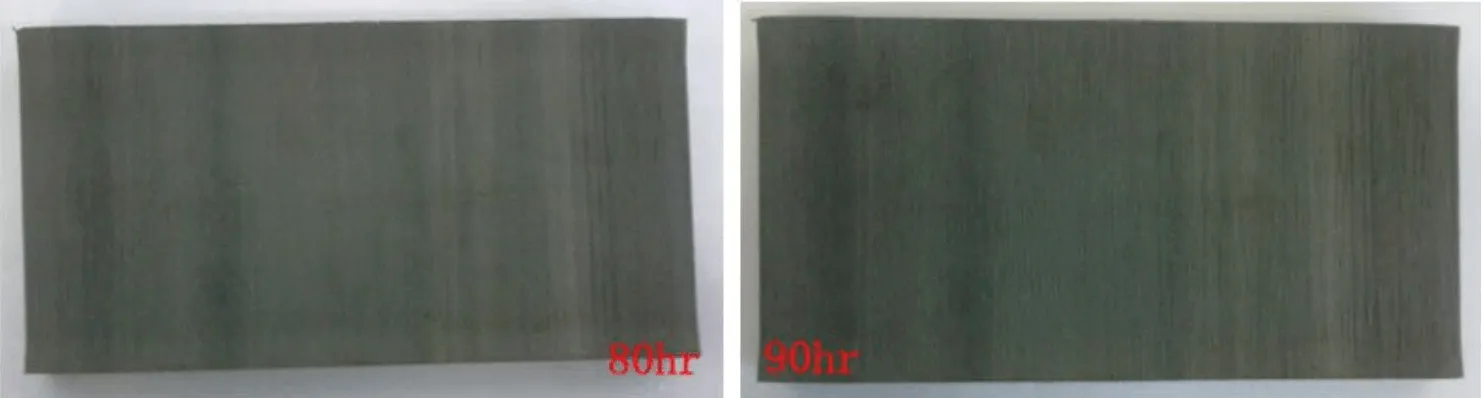

BOILING

- Step 1: Put the test samples in the container (the water level needs to cover the samples by at least 5 mm or more)

- Step 2: Turn on the heating plate to 100 degrees Celsius and record/observe every 2 hours

- Step 3: Samples need to be taken out every day and the duration should be recorded. The duration is recorded after the temperature of the hot plate reaches 100 degrees Celsius

- Step 4: Repeat procedure 1-3 on the second day

PICTURES BELOW SHOW ULTRASHIELD AFTER A 90 HOUR BOILING TEST. THE RESULTS SHOW NO SEPARATION BETWEEN THE CAP LAYER AND THE CORE, NO DAMAGE, AND NO CRACKING

Summary: Tested in a QUV chamber for 3000 hours, experts say no visible color change can be observed at a Delta E < 5.0[/caption]

Summary: Tested in a QUV chamber for 3000 hours, experts say no visible color change can be observed at a Delta E < 5.0[/caption]