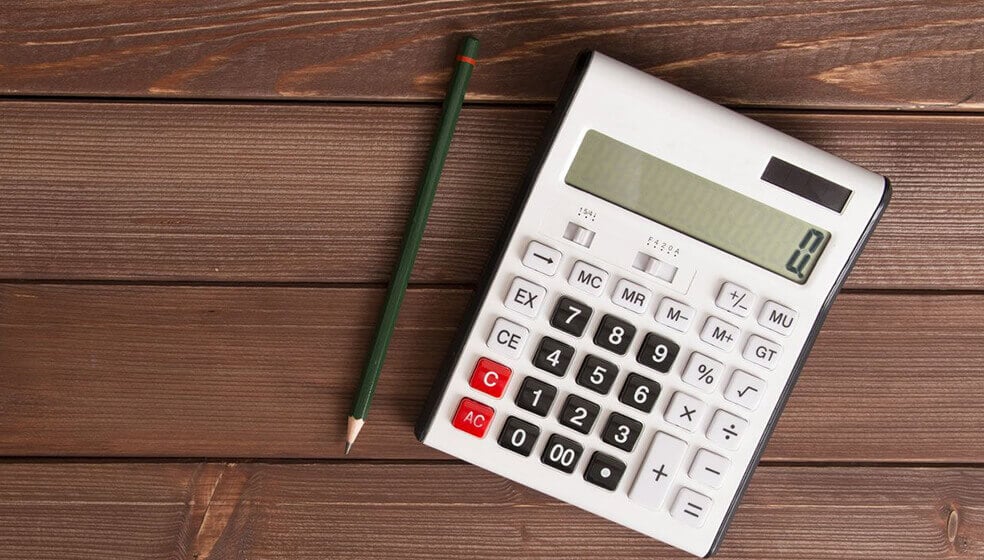

FIVE TYPES OF PE COMPOSITE WOOD IN THE CURRENT MARKET

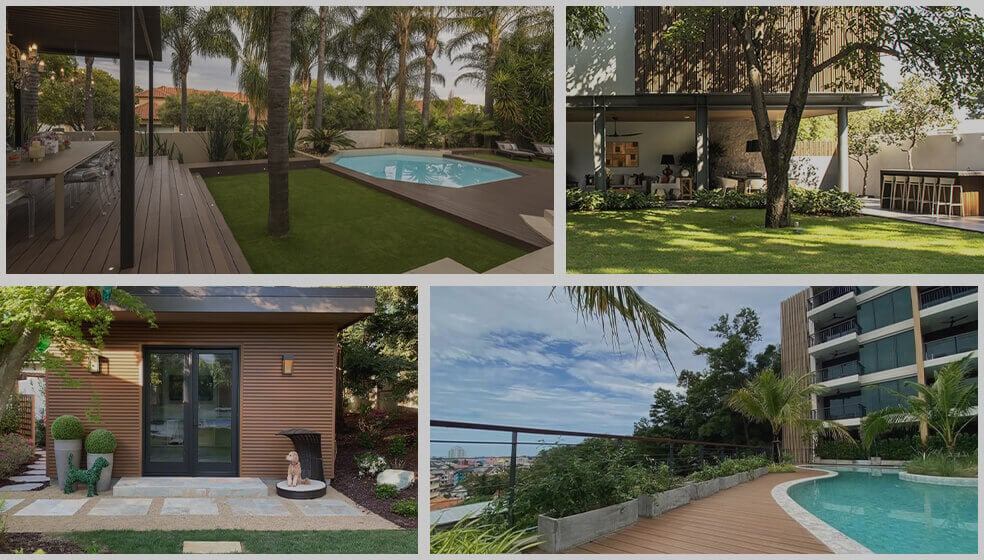

Based on PE composite wood market, they can be divided into capped and non-capped composite wood. Understanding the differences between capped vs. uncapped composite decking can help you with your project.

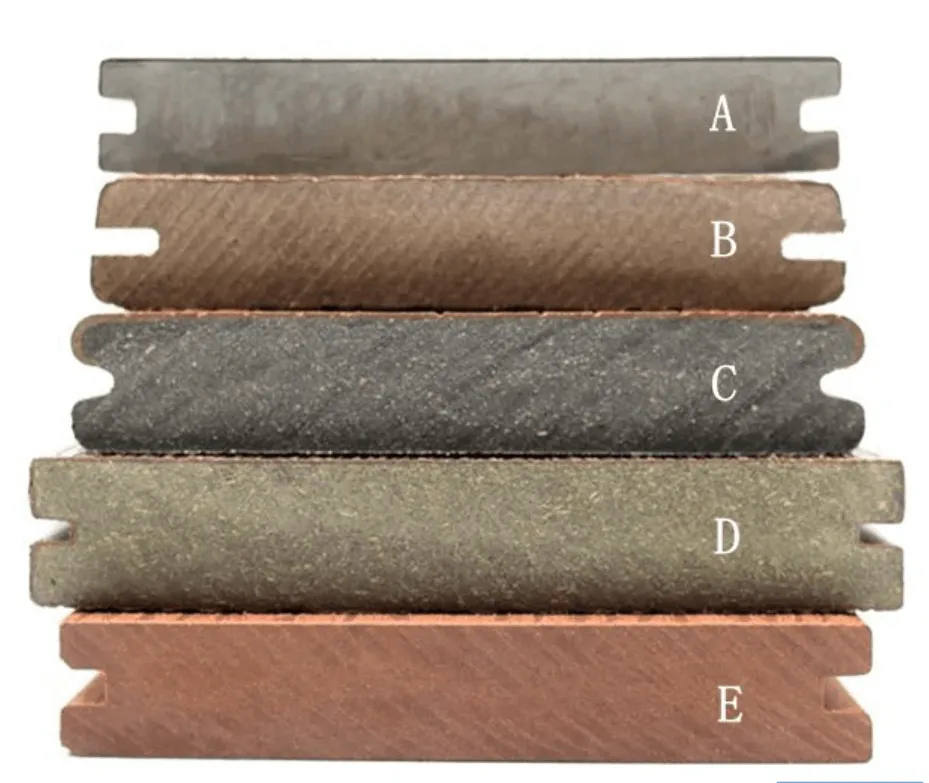

Five different composite decking types can be identified as follows:

E. First generation (non capped) composite wood has no cap layer to protect the core.

D. Some capped composite wood products contain wood powder in their cap layer, which means that wood powder is still exposed to the elements and can still succumb to the problems of the first generation.

When choosing composite decking, capped vs. uncapped is likely to be one of the first decisions to make, and choosing an uncapped material could cost you. Without a capped layer to protect the core, the wood fiber is exposed to the surface and damaged by various harsh weather condition, UV, moisture, bacteria, fungus and mold.

Not only the color will be faded out, the structure and composition will be degraded or even destroyed. Many severe problems have already risen during the past few years in the wood composite market. The difference between capped and uncapped composite decking is stark and will only become more noticeable as your deck ages.

Problems include:

- Crumbling

- Color Fading

- Fungus & Mold & Mildew

- Cracking

- Scratching

- Staining

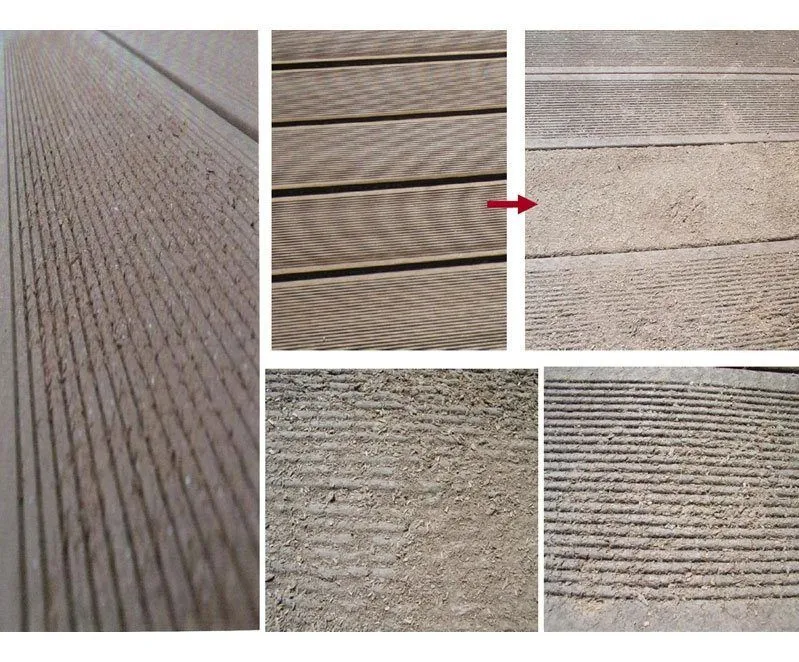

1. CRUMBLING

When the first generation composite boards are exposed to the UV and water it begins to decompose. This is due to an improper amount of bounding agent and antioxidant added to the composite material. Ultimately, the wood fiber absorbs moisture with UV together which causes the composite decking to decay, crumble, deteriorate, and rot.

First generation composite decking is not scratch resistant at all, it can be easily scratched with a person’s fingernail after it has started to weather.

2. COLOR FADING

The reason for color fading comes from the wood fiber content. Wood is naturally going to fade if not protected, and most of the time manufacturers are brushing their boards so that damages the plastic allowing the wood fibers to be exposed to the surface. Inconsistent fading occurs due to the manufacturer’s inability to control the consistency of the colorant and raw materials being added.

COLOR DIFFERENCE – MANY DECKS WERE FADED WITH UNEVEN COLOR RESULTING IN SOME BOARDS BEING LIGHTER AND OTHERS GETTING DARKER.

3. FUNGUS & MOLD & MILDEW

Fungus, Mold, and Mildew problems are usually found in climates with extreme humidity or climate change. The wood fibers are being attacked because they are exposed to the elements and since they are not protected by a sealant or treated.

Many people have tried to use deck cleaners to clean off the mold, but once the layer that is sealed/protected by the cleaner wears off the mold will just attack the other layers below.

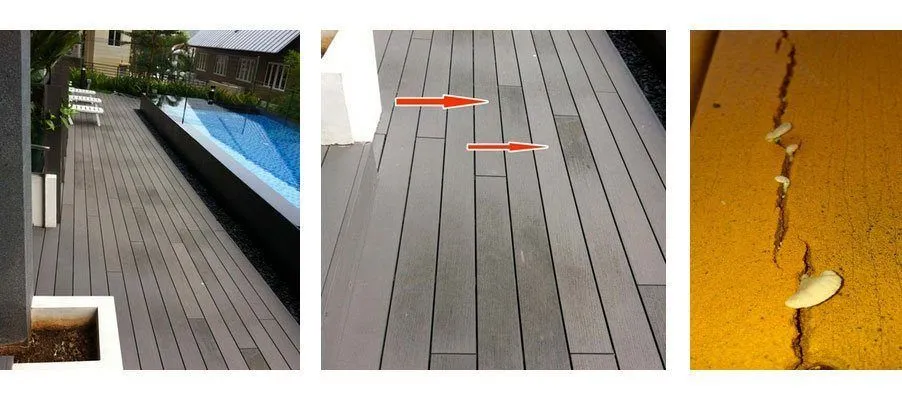

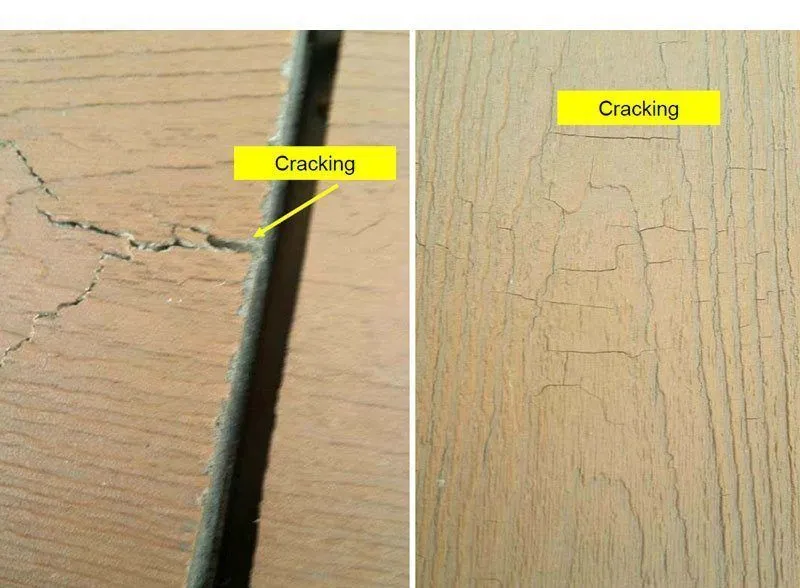

4. CRACKING

Many manufacturers add calcium / filler to their product to enhance the stiffness of the board, but it makes the board more brittle. Therefore, when installers try to drill into the board there is a potential that it might crack.

5. SCRATCHING

The first generation composite’s scratch resistance is very poor and this is due in part because of the wood fibers. Wood fibers inherently have a low scratch resistance and when the manufacturer brushes/sands the board it creates a coarse effect on the surface allowing for even less scratch resistance.

6. STAINING

Without any cap protection, any stains will be absorbed by the wood fiber or penetrate in between the wood fiber and polymer directly and permanently.

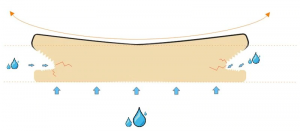

C. Some capped composite wood is only half capped, this solves some problems, but other problems occur

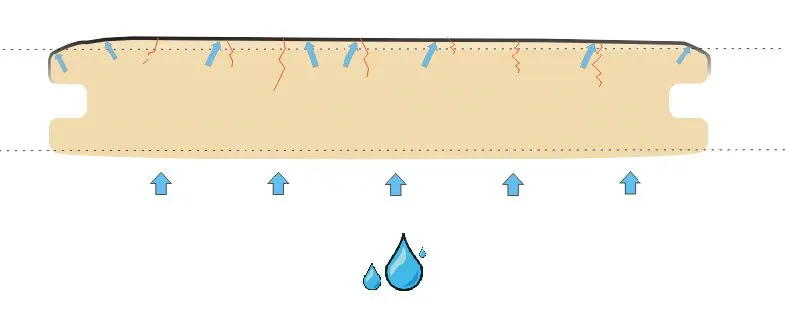

Capping the top half of the board does provide higher stain, scratch, and UV resistance, however, the underside and grooves of the board are exposed to the elements and that creates dry and wet effect on the top and bottom.

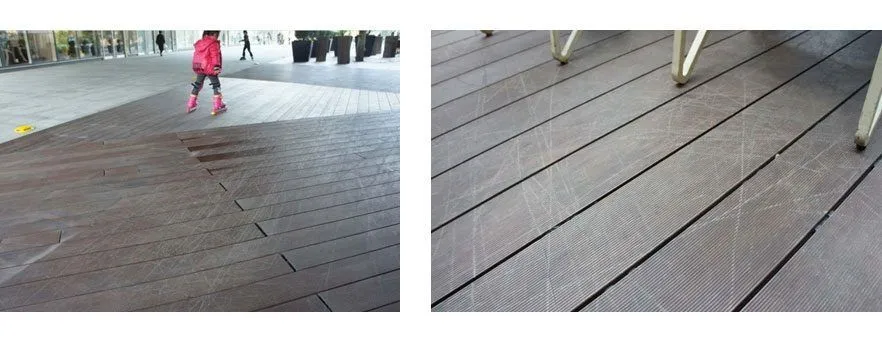

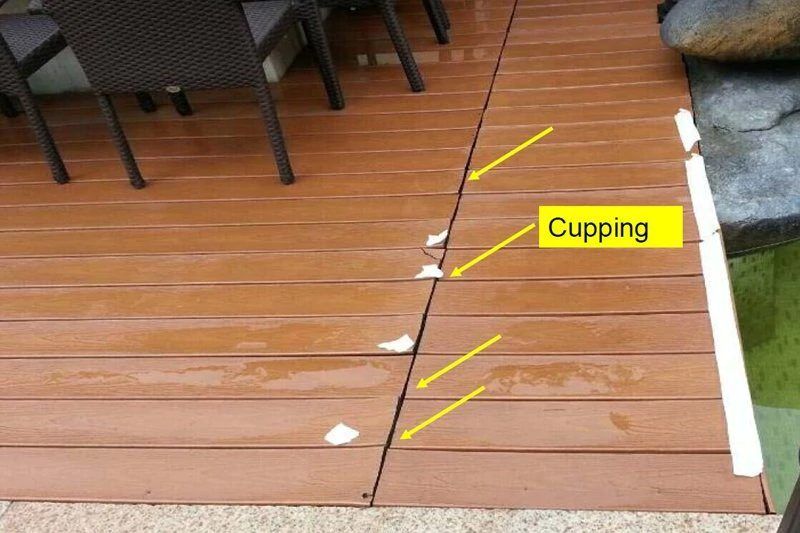

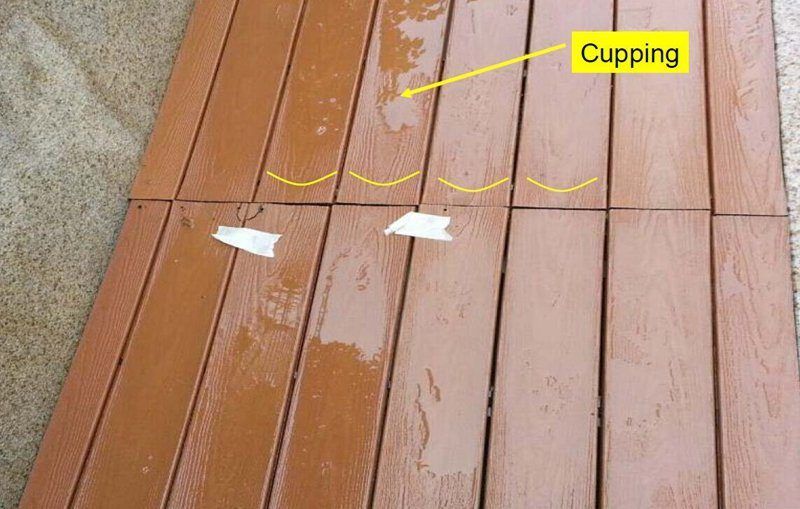

7. SWELLING & CUPPING

The shield uses a virgin engineering grade polymer that has extremely low water absorption rate. The shield on a half capped board is only protecting the top meaning that the bottom is still exposed in a similar fashion as the first generation composite.

Therefore, on a very humid day the bottom will continually absorb moisture and the top will be almost completely dry this creates a cupping/twisting effect on the board similar to real wood. The force of this effect can be so strong that it actually tears/splits the core in half as shown below.

8. CRACKING IN THE CAP LAYER

As the inner core continues to gain moisture the force could get so strong that it tears the cap layer as well.

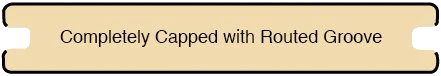

B. Some manufacturers extrude a fully capped board and then cut the grooves on both sides of the board to save money on having one mold do two profiles (grooved and ungrooved).

The other reason could also be that technically they are not as advanced in mold designing. A board with an uncapped groove still allows moisture to be absorbed into the core through the entire length of the board. Therefore, there is a potential for swelling, cupping, and cracking to exist over time.

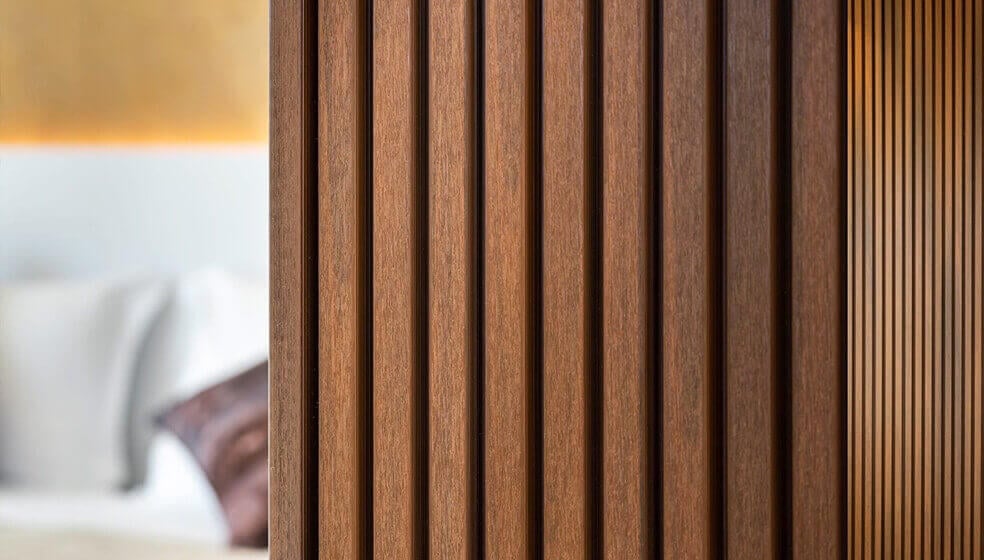

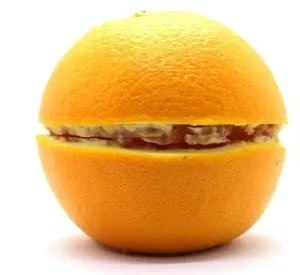

A. Capping 360 degrees provides complete protection all around the board and even in the groove of the board.

This is the only way to complete protect the board from UV, water, insects, and any other mold/mildew from attacking the core.

Note: The core is still susceptible to the outside elements so it is recommended to either use a sealant or end caps to cover up any ends that are not protected.

ULTRASHIELD® ADVANCED CAPPED COMPOSITE MATERIAL

Strong and durable polymer shield capping the core 360 degrees. The Core is made of wood fiber, PE polymer, and additives. The Shield is made of special engineering grade polymer and additives with extremely low water penetration.

The Shield prevents moisture penetration inside the core, resisting problems like:

- No Rotting

- No Splitting & Cracking

- No Fungus & Mold

Note: Mold can still occur on the board through outside substances such as: food, tannins, and etc.that are left on the surface of the board if not cleaned within a reasonable amount of time. Please read the care and cleaning guide to get more information.

The Shield gives maximum protection against:

- Staining

- Fading

- Mold/Mildew

- Scratches

The Shield maintains a pleasant look for years to come and needs no painting, sanding, or oiling of any kind.

If you have questions about whether you should choose capped or uncapped composite decking, get in touch with our experts today. They know the ins and outs of these materials, so they can help you choose what’s best for your project.